MACHINERIES AND ENGINEERING SPARES

KAESER

Kaeser's M350 recently won the Gold 2013 King Award in the Fluid/Pneumatic Power Category from New Equipment Digest. Named after long-time editor, Bob King, the comprehensive awards competition showcases the best new products and the innovation involved with developing them.

Delivering 1,200 cfm at 125 psig, the fuel-efficient Mobilair M350 is the most powerful model in Kaeser Compressor's portable compressor line. The unit includes many of the same features as Kaeser's other Mobilair models — a large fuel tank, easy access to maintenance points, and an anti-frost valve — as well as a low-carbon particulate production diesel engine, an SCR catalytic converter and more.

Atlas Copco GA 30-90 (40-125 HP) VSD Compressors

The Atlas Copco GA 30-90 VSD Lubricated Air Compressor is designed, manufactured and tested in accordance with ISO 9001, ISO 14001 and ISO 1217, Ed. 3, Annex C. The latest generation of Atlas Copco’s patented oil-injected screw element, powered by a maintenance-free drive system, ensures a long and trouble free life at the lowest operating cost. Engineered to provide reliability even in ambient temperatures up to 55°C/131°F, the GA takes reliability to a new level.

The new Atlas Copco GA 160+ and 200-315 Lubricated Air Compressor delivers high quality compressed air at maximum air capacity and the lowest operating cost, even in the harshest conditions such as temperatures up to 46ºC/115ºF.

The Atlas Copco ZA / ZE 3-6 and ZE4 VSD Oil-Free Air Compressor ranges provide 100% pure, clean air that complies with ISO 8573-1 CLASS 0 (2010) certification. CLASS 0 means zero risk of contamination, zero risk of damaged or unsafe products, zero risk of losses from operational downtime, and zero risk of damaging your company’s professional reputation

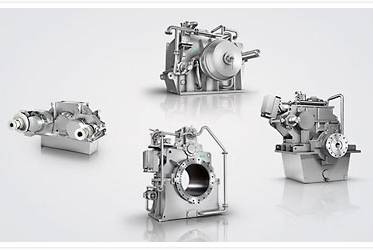

HEAVY DUTY GEAR AND ELECTRIC MOTOR

With MOTOX we are offering the complete range of geared motors. Our portfolio includes all of the usual gear unit types and covers all drive applications. Here you will find the optimum solution for each and every task. Not only this – you will have chosen gear units with higher rated torques than are generally available in the market place.

Modern drive solutions have to withstand the most varied influences, achieve maximum efficiency, and be absolutely reliable. When these requirements are met, high plant availability and low product life cycle costs can be ensured. With the Siemens FLENDER gear units CURRAX offers you the most comprehensive range of industrial gear units in the world.

Simply select the ideal gear unit for your requirements and benefit from the advantages offered to you by our standard range. The high quality, the fast availability worldwide, and the attractive price level are the main strengths of this range of gear units. Horizontal or vertical mounting positions, different versions of helical, bevel and bevel-helical gear units, and the compact design of our gear units give you maximum flexibility in the design of your plant.

HIMMEL® - Agitator geared motors are frequently used in sewage treatment plants, but also in the cosmetic, chemical, pharmaceutical or food sectors. The gear mechanism is generally mounted vertically on the agitator tank.

As the HIMMEL® agitator gear mechanism must withstand high axial and radial forces; as a standard, it is equipped with a reinforced gearbox shaft and a reinforced mounting and therefore possesses high operational reliability

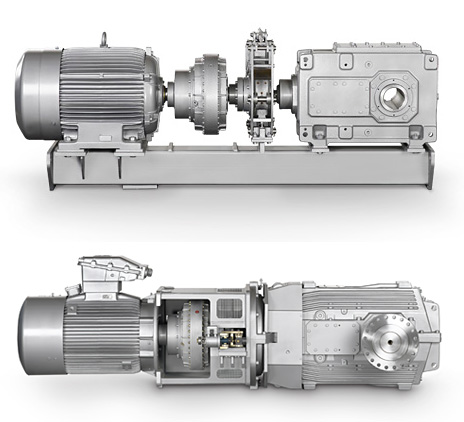

Engineering of complete drive chain solutions for your applications

We design and compose your individual application specific drive technology solution using SIEMENS and FLENDER products and components – up to a complete drive chain.

We combine electrical motors, couplings, brake system, cooling system and gear units to create the most efficient and economical solution.

Universal platform for drive-based applications

SINAMICS covers a broad range of applications on the one hand, and on the other hand represents uniformity thanks to functions such as drive control, operation, and communication, which cover all product families. The particular advantage of having a shared platform: different SINAMICS systems can be flexibly combined depending on the individual requirement – creating a customized drive solution for your application.

SIEMENS Standard motors up to frame size 315

Please check back soon

OUR CLIENTS

HEYETT maintenance programs are one of our strengths when it comes to customer care, allowing us to provide our customers with all the assistance they need to guarantee complete, efficient operation of the instruments together with the highest levels of performance.