BEVERAGE ANALYSER

IB05 ANALYSER

The Maselli IB05 system has been developed over many years of experience and collaboration with the international soft drinks industry. The IB05 measures continuously in-line the concentration and carbonation of regular, no added sugar and diet products. Optional measurements include sugar inversion, % alcohol and dissolved oxygen. Designed for reliable operation in the demanding environment of the soft drinks plant, the IB05 can be fully integrated with the blending and filling process. The IB05 is the heart of the BAS02 monitoring and control system that provides brix and CO2 control, remote display and monitoring, data acquisition, and QA reporting

IB08 ANALYSER

It is nearly time for the opening of the 2014 edition of BrauBeviale, the German trade fair dedicated to technology, logistics and raw materials for the Beverage sector. As always Maselli Misure will be taking part in this important European event, scheduled to take place in Nuremberg between 11 – 13 November.

Innovation and technology will be at the basis of the new instruments which visitors can expect to find in Maselli’s exhibition space, with special focus on the Soft Drinks sector: in fact we will be presenting the new UC07 and IB08 units which respectively measure CO2 values and diet and regular soft drinks.

More specifically, the UC07 is based on proven infrared ATR technology which guarantees reliable on-line units with no moving parts. The IB08, on the other hand exploits Maselli’s well-known pressure-temperature (p/T) system and can be further configured with the UC07 unit.

Simplicity, top performance and reliability of results are the main features which distinguish the innovative liquid analysis systems created by Maselli Misure.

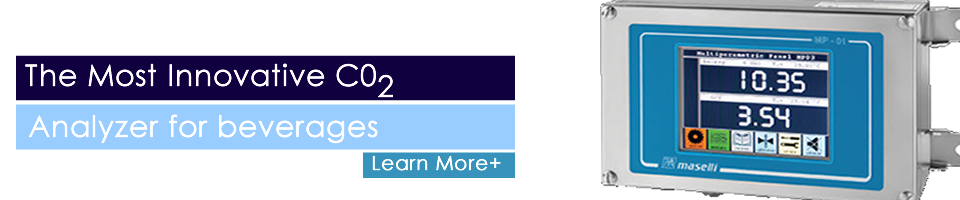

CO2 ANALYSER

Thanks to the experience and research of the Maselli Misure team, the new UC07 has been created: a system for measuring and analyzing CO2 dissolved in beverages based on proven ATR technology. Reliability and precision are at the basis of this modern instrument which simplifies measurement of dissolved CO2, guaranteeing high levels of performance and measurement quality for soft drinks, mineral waters, beers and fruit juices.

BRIX ANALYSER

The UR24 digital refractometer is a stand-alone unit designed for simple installation in-line or in a tank or vessel. It continuously measures concentration and displays and outputs the result in °Brix or % concentration. It also features a user programmable scale for specific applications. The UR24 will signal to the process when concentration is outside of specifications or has reached its target end point.

The UC05 digital carbonation analyser is a stand-alone unit designed for simple integration with existing pipework. It continually measures dissolved CO2 concentration and displays and outputs the result directly in vol/vol or g/l. The UC05 will also signal to the process when carbonation is outside of specification.

The UR22 Brix/Diet analyser is a stand-alone unit designed for simple integration into new and existing processes. It continuously measures regular, no added sugar and sugar free products and displays and outputs the result directly in °Brix or % Diet Standard. The unique optical design of the UR22 provides unrivalled performance on sugar free products and offers a real-time alternative to time consuming manual sampling and laboratory analysis. The UR22 is not affected by the presence of dissolved CO2 or pulp and fibres in the product.

REFERENCE REFRACTORMER

The refractometer is an instrument designed to measure the refractive index of a substance. In turn the refractive index can be correlated to the composition of the sample, for example the concentration of a solute in a solution.

The refractometer, in suitable conditions, can therefore be used as an extremely rapid instrument for measuring the concentration of a solution. Taking this simple but fundamental concept as a starting point, back in the early 1950s Maselli Misure began to develop refractometric units, specializing in the analysis of liquid substances using units installed directly on the line.

The extremely high level of application versatility provided by these instruments, together with their operating principle, soon made them so widely successful on a commercial level that in many industrial sectors they have become an essential process reference tool. Back in the ‘50s the precision reached was somewhere in the region of ±1 Brix; today, following 60 years of research, improvements and continual technological updates, Maselli Misure is now in a position to offer analysis units with an accuracy measured in milliBrix.

MULTI-LABORATORY

Maselli on-line analyzers can be connected to the MULTILAB Data Acquisition and Remote Control system for the transmission, collection and handling of data so that the production line can be controlled, commanded and analyzed in statistics mode from a remote PC (directly from the laboratory for example).This system can communicate simultaneously with eight separate 8 analysis units installed on different lines in the plant.

The MLab section dedicated to remote control allows the operator to control and modify all the functions and parameters set on the various analysis units installed on the line.

The MLAB data acquisition section graphically displays (in real time) the production values and any alarm conditions which may have arisen on the line. It also stores the data for future statistical consultation and allows the user to print off graphic and numerical reports from the archives.

OD01 – Waste Water Monitor

The OD-01 analysis system provides continuous COD trend monitoring of effluent discharge from beverage production plants. It measures effluent where the organic content derives primarily from sugars. The COD value is calculated using a proprietary algorithm based on individual measurements of refractive index, pH and conductivity. This provides a reliable analysis solution that is faster and more economical than complex, conventional methods that use chemical reagents. The OD-01 is designed to operate reliably in typical effluent plant environments without the need for continual maintenance or adjustments. It comprises the following components:

The analyser is a stand-alone system designed to be connected to a submersible pump in the effluent flow or sump. Effluent is then circulated through the self-contained analysis unit. Analyzer cleaning and pump flushing cycles are controlled automatically. The analyzer can be installed on the effluent water outlet of a specific process or on the main collection manifold. The following hook-ups are required for operation of the OD- 01 analysis system:

Measurement data is available via 4-20mA analogue outputs and a digital communications interface. The system can be programmed with alarm thresholds to signal high COD effluent values. The system will also interface with the Maselli Multilab data acquisition system. This provides real-time data and trend displays with data storage for historical analysis and reporting.

OUR CLIENTS

HEYETT maintenance programs are one of our strengths when it comes to customer care, allowing us to provide our customers with all the assistance they need to guarantee complete, efficient operation of the instruments together with the highest levels of performance.